Supercraft Facilities

-

CNC Machining

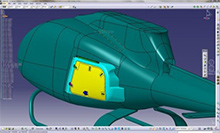

Supercraft have an impressive range of CNC machines, fed by our CATIA 5 CAD systems and VERICUT NC verification software. We have recently purchased two Mazak i-500 5 axis machine centers to supplement our machining capability in our Byfleet workshop.

i-500 VARIAXIS

The latest generation MAZAK i-500, 5-axis machining center, is designed for multi-surface machining, delivering high-speed, high-accuracy performance. A large table size provides an impressive machining envelope of Ø500mm. The i-500 is the latest generation multi-tasking machine providing versatility and performance that is both environmentally friendly and energy efficient.

VRX630 VARIAXIS

This is a twin table machine with a machining capacity of up to 730mm diameter x 500mm thick. This facility enhances productivity so the second operation (twin pallet) produces the completed part reducing number of multiple operations or setups thereby reducing unnecessary time and costs that will reflect on you the customer.

VTC 800/30SR

This life size machine will cover all requirements for large capacity machining such as wing ribs, beams, seat runners and console panels etc. The 3500mm x 900mm table allows material up to 3000 x 880mm to be clamped and machined using all 5 axis capability. In addition smaller parts can be manufactured using the rotary table in the horizontal position. This allows flexibility for the long bed to be divided into two tables reducing down time on machine setting and increasing shorter lead times and increasing machine capacity.

Full Capability:

- 1x Machining Centre vertical - 3 Axis - Hitachi-Seiki VS50 - pallet changer 1000 x 500 mm

- 1x Machining Centre vertical - 3 Axis - Mori-Seiki NV5000 - Hard Metal - 1320 x 600 mm

- 2x Machining Centre vertical - 3 Axis - 1500 x 750 x 750 mm

- 1x Machining Centre vertical - 4 Axis - Mazak i-200 multi-tasking - 1000 x 500 x 710 mm

- 2x Machining Centre vertical - 3 Axis - 560 x 410 x 510 mm

- 4x Mazak 3 Axis Mill - VCS 530C - 1050 x 500 x 610 mm

- 3x Mazak 5 Axis - i500 - 500 x 500 mm

- 2x Mazak 5 Axis - 630 Twin Pallet - 730 x 600 mm

- 2x Mazak 5 Axis - VTC 800/30SR - 3000 x 900 mm -

- 1x Mazak 5 Axis Integrex i200 - Mill Turn Machine - X 615, Z 1077, Y 250 mm

- 1x Mazak 200 CNC Lathe

- 1x Mazak 200 CNC Mill/Turn Centre - Bar Feeder

- 2x Bridgeport Manual Mill

- 1x X&Y Manual Mill

- 2x Colchester Lathe

-

Fabrication

- CNC 3 Axis water jet profiling machine - 8’ x 4’ Bed

- CNC Turret punch-press Weidman - 8’ x 4’ Bed

- 2x CNC Wadkin Router 2750 x 1500 x 300 mm

- 2x Trumpf CNC 6 Axis Brake Press

- CNC 25 ton Brake Press

- Rubber Press 500 ton

- Power Press 100 ton

- Power Press 55 ton

- Power Press 25 ton

- Eckolds Forming Machine

- Extensive range of sheet metalwork equipment

-

Welding

- Aluminium spot welding 45” Throat

- Seam Welding

- 4x Tig Welding bays

- 2x Mig Welding sets

- Orbital Welding Equipment

-

Treatments

- PDF Lines soft and hard metals

- Alachrom 1200

- Chromic Anodising for high corrosion resistance on aluminium parts

- 2x Paint booth and stoving ovens

Heat Treatments

- Air recirculating furnace for heat treatment of aerospace alloys for solution treatments: Hardening, Tempering, Annealing, Normalising

- 2x Air recirculating ovens for aerospace precipitation

-

Quality

- 2x CMM Interface to CAD CAM - 4 m x 1 m

- Fluorescent dye crack detect

- Hardness Testing

- Pressure & leak test facility 250 PSI

- Tensile Testing

- Part marking - Electro etch, vibro etch & ink

-

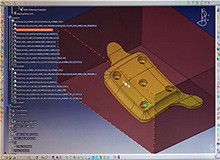

CNC Programming

CATIA & VERICUT

Supercraft’s CATIA CAD system accepts 3D models from the customer in a form that has tolerance and annotation information applied and associated directly with the 3D model. Digital simulation of cutting procedures are defined within the software and NC code produced for the CNC machines. The NC code is verified with VERICUT software to ensure it is valid for the destination machine. Upon verification NC code is uploaded to the machine in the workshop.

- CATIA V5 Seats (5x)

- RADAN Seats (2x)

- VERICUT NC verification

-

Programming & Inspection

- Laservision - Pipe Inspection and Correction

- Eaton Leonard Vector Tube Data Center

-

Pipe Manufacturing

- Evebend - Min 5.00mm Max 10.00mm

- VB25 Eaton Leonard - Min 5.00mm Max 18.00mm

- VB40 Eaton Leonard - Min 5.00mm Max 40.00mm

- Mewag Large Bore - Min 25.00mm Max 100.00mm

- VB150 Eaton Leonard - Min 5.00mm Max 40.00mm

- VB76 Eaton Leonard - Min 30.00mm Max 76.00mm

- Unison EB1000 - Min 5.00mm Max 18.00mm

- Unison Breeze - Min 5.00mm Max 40.00mm

- Permaswage

- SBAC STD Swaging Technique

- Oxygen pipe cleaning rig

- Pipe pressure test rig - 12,000psi

- PFD

- Titanium welding chamber

- Pickling, Flushing and Oxycleaning

- Anodising and Alochrome Finishing

- Welding

- Heat Treatment

- Part marking - Electro etch, vibro etch & ink

- Fluorescent Dye Penetrant Inspection, Tensile and Pressure Testing

-

Treatments

- Pre-Weld cleaning line

- TSA Anodisingm and Paint Facility

-

Fabrication

- 1.8m x 1.2m Rubber Press

- Various general fabrication equipment